Kev xaiv ntawm dyeing thiab xov txheej txheem yog tsuas yog nyob ntawm ntau yam, specifications thiab tiav cov khoom yuav tsum tau ntawm cov ntaub, uas yuav muab faib ua pre-kev kho mob,dyeing, printing, post-finishing thiab lwm yam.

Kev kho mob ua ntej

Ntuj fibers muaj impurities, nyob rau hauv lub textile ua txheej txheem thiab ntxiv slurry, roj thiab paug cov av, lub hav zoov ntawm cov impurities, tsis tsuas yog cuam tshuam qhov kev vam meej ntawm dyeing thiab xov ua tiav, tab sis kuj muaj feem xyuam rau lub hnav kev ua tau zoo ntawm cov ntaub.

Lub hom phiaj ntawm kev kho mob ua ntej yog siv tshuaj lom neeg thiab lub cev ua haujlwm kom tshem tawm cov impurities ntawm cov ntaub, ua rau cov ntaub dawb, mos, thiab muaj cov permeability zoo kom tau raws li qhov yuav tsum tau ua, thiab muab cov khoom tsim nyog rau dyeing, luam ntawv thiab xov.

Paj rwb: raw ntaub npaj, singeing, desizing, boiling, bleaching, mercerizing. Polyester: daim ntaub npaj, ua kom zoo (kua alkali, thiab lwm yam), preshrinking, reservation, alkali deweighting (kua alkali, thiab lwm yam).

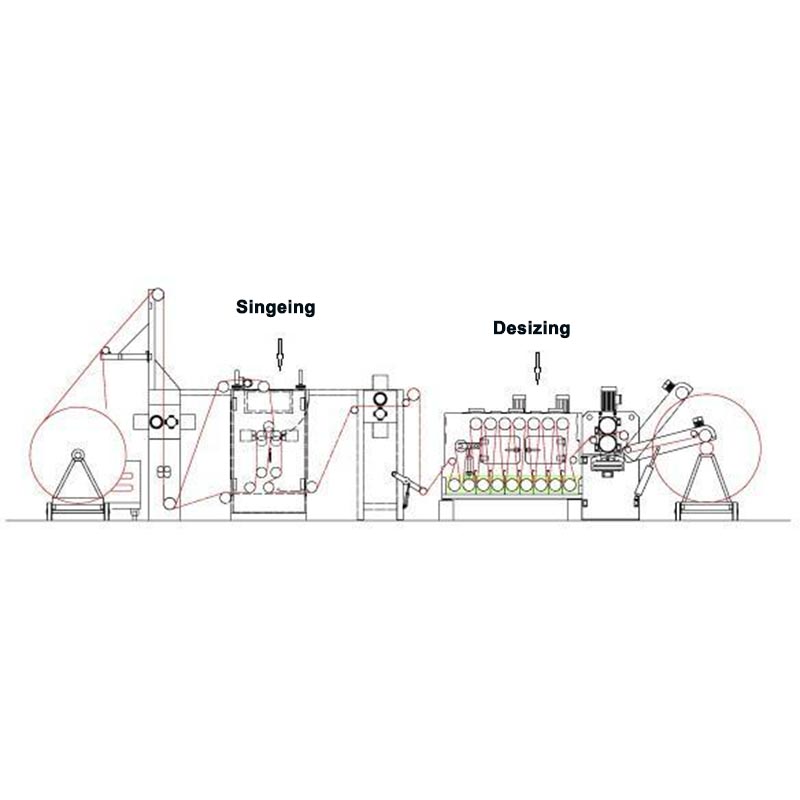

Hu nkauj

Feem ntau, tom qab nkag mus rau hauv lub tshuab luam ntawv thiab dyeing Hoobkas los ntawm textile mill, cov ntaub grey yuav tsum xub kuaj xyuas, tig, batching, luam ntawv thiab xaws, thiab ces hu nkauj.

Yog vim li cas:

(1) ntawm daim ntaub tsis singeing ntau dhau, sib txawv ntev;

(2) cov degree ntawm kev ua tiav tsis zoo, yooj yim kis kab mob;

(3) nyob rau hauv ib theem zuj zus zhongyi ntaub plaub dyeing thiab xov, luam ntawv thiab dyeing tsis xws luag.

Singing lub hom phiaj:

(1) txhim kho daim ntaub luster; Txhim kho qhov tiav;

(2) txhim kho pilling kuj (tshwj xeeb tshaj yog cov tshuaj fiber ntau ntaub);

(3) txhim kho cov style, singeing yuav ua rau cov ntaub ua nkig, yog pob txha.

Desizing

Nyob rau hauv cov txheej txheem weaving, lub warp yog raug ntau dua nro thiab kev sib txhuam, uas yog ib qho yooj yim rau tawg. Txhawm rau kom tsis txhob muaj kev sib tsoo, txhim kho kev ua haujlwm ntawm cov ntaub thiab cov ntaub grey zoo, nws yog ib qho tsim nyog yuav tsum tau sizing lub warp yarn ua ntej weaving. Cov fiber ntau hauv cov xov paj tuav thiab tuav ua ke, thiab tsim cov khoom slurry zaj duab xis ntawm cov xov paj, ua rau cov xov paj nruj thiab du, yog li txhim kho lub zog tawg thiab hnav tsis kam ntawm cov xov paj.

Desizing lub hom phiaj: Tom qab sizing, slurry nkag mus rau hauv cov fibers thiab ib nrab txuas mus rau saum npoo ntawm warp. Thaum txhim kho kev ua haujlwm ntawm cov xov paj, cov slurry pollutes dyeing thiab tiav cov kua ua kua, cuam tshuam cov tshuaj sib cuam tshuam ntawm cov fibers thiab dyeing thiab tshuaj cov ntaub ntawv, thiab ua rau nws nyuaj rau nqa tawm dyeing thiab ua tiav.

(1) Taw qhia txog kev siv slurry

Natural slurry: hmoov txhuv nplej siab, seaweed pos hniav, pos hniav, thiab lwm yam.

Starch zog:

① nyob rau hauv cov ntaub ntawv ntawm acid decomposition;

② nyob rau hauv cov ntaub ntawv ntawm alkali stability, o;

③ nyob rau hauv cov ntaub ntawv ntawm oxidants yuav decomposed;

④ los ntawm cov hmoov txhuv nplej siab decomposition enzyme decomposition.

Tshuaj slurry: cellulose derivatives xws li hydroxymethylcellulose (CMC), polyvinyl cawv (PVA), polyacrylic acid, polyester, thiab lwm yam.

PVA khoom:

① ruaj khov rau cov kua qaub thiab lub hauv paus, viscosity tsis txo;

② Nws yog degraded los ntawm oxidant.

③ Kev siv dav dav, zoo sib xws, tsis muaj kev sib xyaw ua ke

(2) Feem ntau siv desizing txoj kev

1. Alkaline desizing

Ib txoj hauv kev siv ntau tshaj plaws hauv cov nroj tsuag dyeing, tab sis tus nqi desizing tsis siab, thiab lwm yam impurities tuaj yeem raug tshem tawm thaum desizing.

Mechanism: Kev siv cov tshuaj sodium hydroxide dilute cov tshuaj kho, cov hmoov txhuv nplej siab slurry nyob rau hauv qhov kev txiav txim ntawm alkali o (los yog o) tshwm sim, tsis tshwm sim cov tshuaj tiv thaiv, kom cov slurry los ntawm gel rau sol, txo cov binding quab yuam ntawm cov fiber thiab slurry, thiab ces siv ntxuav thiab mechanical quab yuam kom tshem tawm nws. Rau PVA thiab polyacrylate slurries, nws muaj peev xwm yaj sodium hydroxide hauv dilute daws.

(cov hmoov txhuv nplej siab) enzyme desizing

Enzymes tseem hu ua enzymes, biocatalysts.

Nta: siab desizing tus nqi, tsis raug mob fiber, tsuas yog rau cov hmoov txhuv nplej siab, tsis tuaj yeem tshem tawm impurities.

Nta: a. Kev ua haujlwm siab. b. Specificity: Ib qho enzyme tuaj yeem ua rau tsuas yog ib qho tshuaj tiv thaiv lossis txawm tias cov tshuaj tiv thaiv tshwj xeeb. c. Cov haujlwm no cuam tshuam los ntawm qhov kub thiab txias thiab PH tus nqi.

Rau cov hmoov txhuv nplej siab los yog cov hmoov txhuv nplej siab sib xyaw (cov ntsiab lus ntawm cov hmoov txhuv nplej siab yog qhov tseem ceeb), amylase tuaj yeem siv rau desizing.

Acid desizing

Daim ntawv thov hauv tsev tsis yog ntau, vim tias kev siv yooj yim rau kev puas tsuaj fiber ntau, ntau ua ke nrog lwm txoj kev. Txoj kev ob kauj ruam yog saws: alkali desizing - acid desizing. Acid desizing tuaj yeem ua cov hmoov txhuv nplej siab hydrolyze, tshem tawm cov ntxhia ntsev thiab lwm yam, thiab ua kom sib haum..

Oxidation desizing

Oxidizing tus neeg sawv cev: NaBrO2 (sodium bromite) H2O2, Na2S2O8, (NH4) 2S2O8, thiab lwm yam.

Lub hauv paus ntsiab lus: Tus neeg sawv cev oxidizing tuaj yeem oxidize thiab degrade txhua yam slurry, nws qhov hnyav molecular thiab viscosity raug txo kom tsawg, cov dej solubility tau nce, thiab cov slurry yog tiv thaiv los ntawm adhering rau fiber ntau, thiab tom qab ntawd cov hydrolyzate raug tshem tawm los ntawm kev ntxuav kom zoo.

(1) Boiling

Lub hom phiaj ntawm boiling yog tshem tawm fiber ntau impurities thiab txhim kho cov khoom ntawm cov ntaub, tshwj xeeb tshaj yog cov wettability.

Ntuj impurities: Rau cov paj rwb ntshiab, feem ntau fiber ntau co-organisms los yog cov kab mob txuam nrog, xws li roj ciab, pectin, protein, tshauv, pigment thiab cottonseed shells.

Artificial impurities: impurities xws li roj, antistatic tus neeg saib xyuas thiab roj, xeb thiab residual slurry ntxiv hauv spinning thiab weaving ua.

Cov impurities no cuam tshuam rau lub wettability ntawm cov ntaub thiab cuam tshuam cov dyeing thiab xov ntawm cov ntaub, thiab yuav tsum tau muab tshem tawm nyob rau hauv lub scouring system nrog sodium hydroxide raws li lub ntsiab thiab surfactants ua tus pab.

(2) Ua kom dawb huv

Tom qab boiling, feem ntau ntawm cov natural thiab dag impurities ntawm lubntaubraug tshem tawm, tab sis rau bleached thiab lub teeb-xim ntaub, bleaching kuj yuav tsum tau. Uas yog tshem tawm pigment, txhim kho whiteness raws li lub ntsiab lub hom phiaj ntawm bleaching ua.

Cov tshuaj fiber ntau tsis muaj cov xim, tom qab boiling tau dawb heev, thiab paj rwb fiber ntau tom qab scouring pigment tseem muaj, lub whiteness tsis zoo, yog li bleaching tsuas yog rau tej yam ntuj tso impurities ntawm paj rwb fiber.

(3) Bleach

Oxidation hom: sodium hypochlorite, hydrogen peroxide thiab sodium chlorite, thiab lwm yam, feem ntau yog siv hauv paj rwb fiber ntau thiab cov ntaub sib xyaw.

Txo: NaHSO3 thiab kev tuav pov hwm hmoov, thiab lwm yam, feem ntau yog siv rau cov ntaub ntawv fiber ntau.

(4) Sodium hypochlorite bleaching:

Sodium hypochlorite bleaching feem ntau yog siv rau bleaching paj rwb ntaub thiab paj rwb blended fabrics, thiab tej zaum kuj siv rau bleaching polyester paj rwb blended fabrics. Txawm li cas los xij, nws tsis tuaj yeem siv rau bleaching protein fibers xws li txhob lo lo ntxhuav thiab ntaub plaub, vim hais tias sodium hypochlorite muaj kev puas tsuaj rau cov protein fibers, thiab ua rau cov fibers yellowing thiab puas. Nyob rau hauv cov txheej txheem bleaching, ntxiv rau kev puas tsuaj ntawm ntuj pigments, paj rwb fiber nws tus kheej kuj yuav raug puas tsuaj, yog li ntawd, nws yog tsim nyog los tswj cov txheej txheem bleaching tej yam kev mob, thiaj li hais tias cov tsos zoo thiab sab hauv yog tsim nyog.

Sodium hypochlorite yog ib qho yooj yim los tsim, tus nqi qis, sodium hypochlorite bleaching ua haujlwm yooj yim, cov cuab yeej siv yooj yim, tab sis vim tias sodium hypochlorite bleaching tsis zoo rau kev tiv thaiv ib puag ncig, yog li nws maj mam hloov los ntawm hydrogen peroxide.

(5) Hydrogen peroxide bleaching H2O2:

Hydrogen peroxide, tseem hu ua hydrogen peroxide, muaj cov mis molecular H2O2. Hydrogen peroxide bleaching yog hu ua oxygen bleaching. Kev ruaj ntseg ntawm cov tshuaj hydrogen peroxide yog qhov tsis zoo nyob rau hauv cov xwm txheej alkaline. Yog li ntawd, kev lag luam hydrogen peroxide yog qaug zog acidic.

Npuag bleached nrog hydrogen peroxide muaj zoo whiteness, ntshiab xim, thiab tsis yooj yim rau yellowing thaum khaws cia. Nws yog dav siv nyob rau hauv bleaching paj rwb ntaub. Oxygen bleaching muaj kev hloov pauv ntau dua li cov tshuaj chlorine bleaching, tab sis hydrogen peroxide yog siab dua li sodium hypochlorite tus nqi, thiab oxygen bleaching yuav tsum tau siv cov khoom siv stainless hlau, kev siv hluav taws xob loj dua, tus nqi siab dua li cov tshuaj chlorine.

Tam sim no, txoj kev qhib dav dav siv tshuaj dawb yog siv ntau hauv kev luam ntawv thiab dyeing factories. Txoj kev no muaj cov qib siab ntawm kev txuas ntxiv, automation thiab kev ua haujlwm ntau lawm, cov txheej txheem yooj yim ntws thiab tsis tsim cov pa phem ib puag ncig.

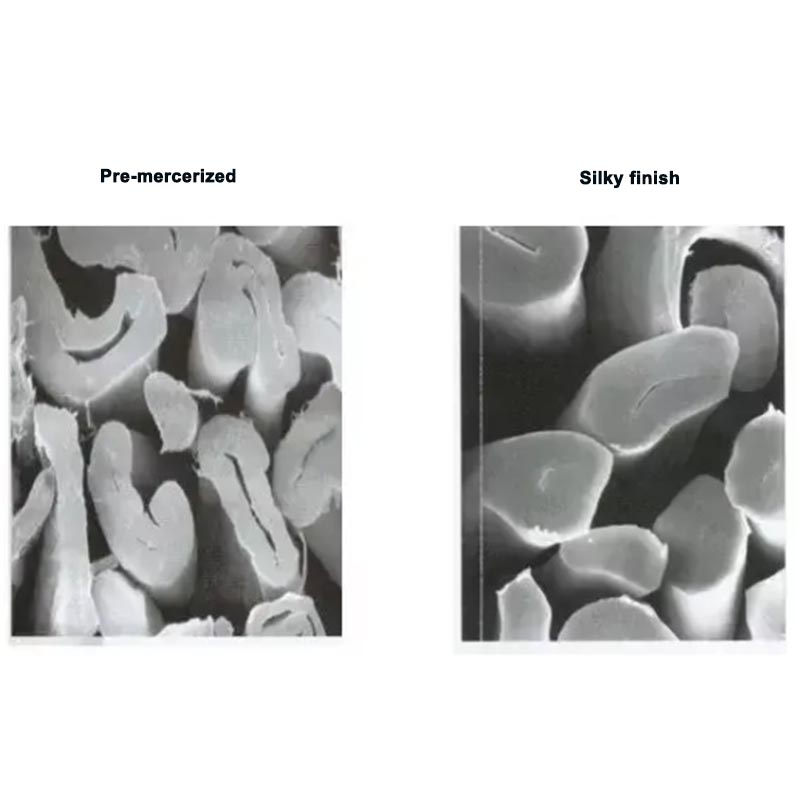

5. Mercerized (paj rwb ntaub)

Textiles nyob rau hauv ib tug tej lub xeev ntawm nro, nrog kev pab los ntawm concentrated caustic soda, thiab tswj qhov yuav tsum tau loj me me, yuav tau txais ib tug silky luster, cov txheej txheem no hu ua mercerization.

(1) Lub hom phiaj ntawm mercerization:

A. Txhim kho lub ntsej muag gloss thiab kev xav ntawm cov ntaub, vim qhov o ntawm cov fiber ntau, cov txheej txheem fiber ntau zoo dua, thiab qhov kev xav ntawm lub teeb pom kev zoo dua, yog li txhim kho cov gloss.

B.Increase tus nqi ntawm dyeing xim tom qab mercerizing tiav, fiber cheeb tsam txo, amorphous cheeb tsam nce, thiab dyes muaj feem ntau nkag mus rau fibers, colouring npaum li cas mercerized paj rwb fiber ntau nce los ntawm 20%, thiab brilliance txhim kho, nyob rau tib lub sij hawm nce tus tuag pem hauv ntej npog lub hwj chim.

C.Txhim kho qhov ruaj khov mercerizing tau ua tiav cov txiaj ntsig tsim, tuaj yeem tshem tawm cov hlua khi, ntau tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm dyeing thiab luam ntawv ib nrab-thiab-ib nrab khoom. Qhov tseem ceeb tshaj plaws yog tias tom qab mercerizing, kev ruaj ntseg ntawm cov ntaub nthuav dav deformation tau zoo heev, yog li txo qis tus nqi ntawm cov ntaub.

6. Refining, pre-shrinking (tshuaj fiber ntau ntaub)

Lub hom phiaj ntawm refining pre-shrinking yog tsuas yog tshem tawm cov roj, slurry thiab av adsorbated ntawm cov ntaub (fiber) thaum lub sij hawm weaving cia thiab tsheb thauj mus los, thiab nyob rau tib lub sij hawm, ib co oligomers ntawm lub fiber kuj yuav yaj nyob rau hauv high kub refining. Cov ntaub grey yuav tsum tau muab tso ua ntej ua ntej cov alkali, thiab cov additives xws li olein thiab caustic soda yuav tsum tau ntxiv. Pretreatment ntawm chemical fiber ntaub yog nqa tawm nyob rau hauv high kub thiab siab dyeing tshuab.

7.Alkali txo (tshuaj fiber ntau ntaub)

(1) Lub hauv paus ntsiab lus thiab cov nyhuv ntawm alkali txo

Alkali txo kev kho mob yog cov txheej txheem ntawm kev kho polyester ntaub nyob rau hauv kub kub thiab concentrated burning lye. Polyester fiber yog hydrolyzed thiab tawg los ntawm ester daim ntawv cog lus ntawm polyester molecular saw nyob rau saum npoo ntawm cov fiber ntau hauv sodium hydroxide aqueous tov, thiab hydrolysis cov khoom nrog txawv polymerization degrees yog tsis tu ncua, thiab thaum kawg dej-soluble sodium terephthalate thiab ethylene glycol yog tsim. Cov cuab yeej txo qis Alkali feem ntau suav nrog cov tshuab dyeing dhau lawm, tsis tu ncua lub tshuab txo qis, cuam tshuam txo lub tshuab peb yam, tshwj tsis yog lub tshuab dyeing dhau lawm; Nruam thiab sib quas ntus txo cov tshuab tuaj yeem rov ua dua cov lye seem. Txhawm rau kom muaj kev ruaj ntseg ntawm cov duab zoo thiab qhov loj ntawm daim ntaub grey rau qee cov khoom txo qis alkali, nws yog ib qho tsim nyog yuav tau ntxiv cov txheej txheem ua ntej, thiab tom qab ntawd nkag mus rau cov txheej txheem dyeing.

Post lub sij hawm: Feb-28-2025